We use a special molding aluminum and silicone alloy permitted for direct contact with the foodstuffs. Aluminum ingots are smelted in the furnaces at about 660°C.

Out of each melt, we take a sample for optical emission spectrographic analysis to define the alloy composition at molecular and atomic levels. It helps us define the concentration of all components for identification of grade.

Accurately measured quantity of metal of a certain temperature is poured into a mold from the holding furnace. The die is an individual tooling designed for each product in our range (in-house NMP design and manufacturing). To form the ingot, hydraulic pressing machine closes down the die with a weight of up to 400 tons. After the die closure, molten metal takes the shape and crystallizes while cooling down. This technology is called crystallization pressure molding. The obtained ingot is sent to mechanical treatment stage: bottom and edge grooving. This kind of molding has advantages as compared to other molding types: lack of micropores in an ingot, because the air bubbles are displaced from the melt under high pressure.

Cookware undergoes multiple treatment stages including surface roughing, tempering, washing and drying. Then, non-stick coating is applied to the cookware by spraying in the painting booths of the conveyor painting line. The guns spray the coating automatically. The coating is multilayered, accuracy of each coat is 2 microns. First, the surface is primed: the primer provides for adhesion between the coating and metal. Interim and finish coats ensure durability and non-sticking. The final operation is the coating baking. Temperature and time parameters of baking are critical.

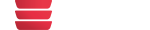

Before the ingot turns into a finished product, some finishing operations are required. Bottom grooving: for creating a mirror-like even surface of bottom to make the cookware steady and for its better contract with the cooktop. Boring and threading at the automatic line in order to attach the durable and convenient fitting to the pan.

Laser marking of the products with individual serial numbers is a quality warranty of original products. The marking indicates some product parameters: series, induction bottom, manufacturing date. It allows offering the aftersales services for partners and personalized warranty service for the buyers.

Each product lot undergoes a set of comprehensive tests. We test the coating color and texture against a reference sample, bonding strength (adhesion), total thickness of coating after baking, coating integrity under the microscope (×20 magnification), no bubbles, cracks, inclusions are allowed. Using the microscope, we also assess the coating exposure to hydrochloric acid. Acid can penetrate the pores of the non-sticking coating towards metal having the ability to displace hydrogen from hydrochloric acid. It causes emission of gas bubbles.